Marine equipment is an integral part of the entire offshore construction system. Marine winches and cranes are key players among them. There is a great demand for the transmission of signals and power between fixed and rotating parts of marine equipment. For this transmission, a slip ring is required. JINPAT Electronics is a manufacturer of […]

Marine equipment is an integral part of the entire offshore construction system. Marine winches and cranes are key players among them. There is a great demand for the transmission of signals and power between fixed and rotating parts of marine equipment. For this transmission, a slip ring is required.

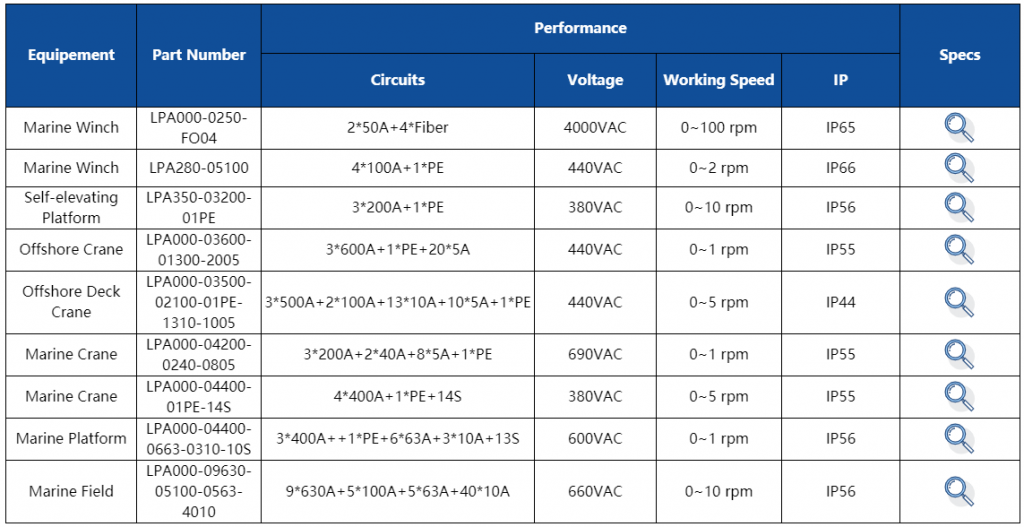

JINPAT Electronics is a manufacturer of slip rings. Since its establishment in 1996, JINPAT has been engaged in the research and development of slip rings and rotating joints. Through years of hard work in the industry, JINPAT Electronics has developed a mature development and production system for slip rings of various types and sizes. For marine equipment, JINPAT also offers many slip ring solutions.

Among JINPAT slip rings for offshore platforms, most are designed for offshore cranes and offshore winches. The latest model of JINPAT slip ring is designed for offshore crane. This latest high capacity slip ring has the code LPA000-03300-01PE-0350-0210-16S. JINPAT, with its long history and experience in slip ring research and development, is able to complete the design and production of the structure in a relatively short time.

The large current slip ring LPA000-03300-01PE-0350-0210-16S consists of 2 modules. There are 3 300A power channels and 1 ground wire in the module of slip ring large. This part takes over the friction vapors of the carbon brush. The operating voltage of the two parts is 690 VAC and 380 VAC. The other module is the weak current signal module. This last module is integrated in a special contact ring with a through hole. It consists of two 10 A 220 VAC channels and 16 24 VAC weak current channels.

In terms of environmental adaptability, since protection measurements are already carried out on application platforms, the current slip ring with IP44 can operate stably at temperatures ranging from -10℃ ~ + 45℃ with 90% humidity. To cope with cold conditions, a 200W thermostat is built into the slip ring to heat the component. Thanks to the thermostat and cooler, JINPAT’s large diameter slip ring shows great flexibility in case of adaptation.

Features and Benefits

◆Photoelectric/high frequency and electrical integration

◆High conductivity, large safe current carrying capacity

◆ Equipped with heat sink and automatic heater.

◆ Mist, corrosion and acid protection, vibration and shock resistance

◆ Low electrical noise, low transmission losses

◆ Additional aperture size

◆ Long service life

◆ Customization available

JINPAT photovoltaic slip rings have high quality and competitive price. JINPAT has provided hundreds of models of electro-optical rotary joints for both civil and military industries. Most of JINPAT electro-optical slip rings have high transmission capacity. High-end slip rings can transmit 4K@60FPS high-definition video signals. OVERVIEW Design product sketches and models using SOLIDWORKS 3D Computer […]

With many years of experience in managing various types of projects, the management team of JINPAT is able to eliminate all obstacles that arise during the execution of projects to ensure that the technology is followed and the products are manufactured successfully. In addition, JINPAT understands the importance of good documentation. Documents such as certificates […]

JINPAT carries out precision machining of all components of its products. At all stages of production, from drawing to molding, JINPAT is committed to being precise and ensuring that the best slip rings are produced. With the ability to machine parts to a tolerance of 5 microns, our experienced, highly skilled team uses the latest […]

JINPAT welding technicians are experts in Gas Metal Arc Welding (GMAW), Flux Cored Arc Welding (FCAW), Gas Tungsten Arc Welding (GTAW) and Semi Metal Arc Welding (SMAW). They are dedicated individuals who value precision and aesthetics in the production of machine components. OVERVIEW Welding procedures comply with codes such as ASMEIX, AWS, DIN, API, B31.1, […]

JINPATElectronics is a customer-oriented corporation. We do our utmost to provide our customers with high-standard solutions for transmission including rotation. Up to now, JINPAT has provided its services to more than 10,000 customers worldwide. Each slip ring produced by JINPAT undergoes a series of rigorous and systematic inspections and durability tests before being delivered to […]

With advanced testing and measuring devices, JINPAT’s Quality Control Department conducts systematic inspections of our products. Our quality measurement system complies with ISO 9001:2015. JINPAT has great confidence in its products and has earned a good reputation for producing products of unrivaled quality. REVIEW Detailed inspection and provision of data in the form of documentation […]