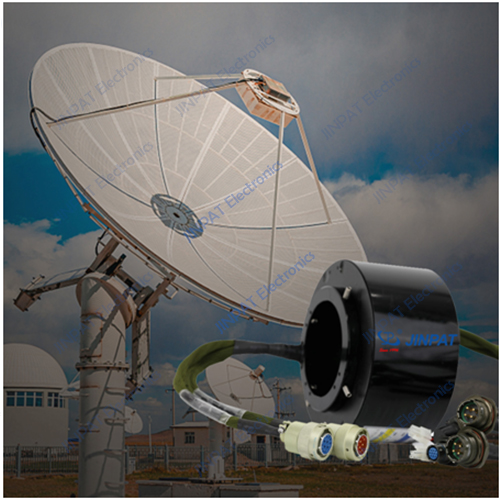

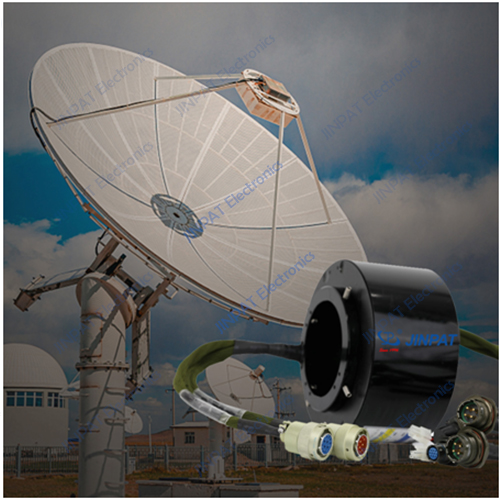

Through-hole slip rings are the second largest production of JINPAT products. This type of slip rings is widely applied in various industries and people’s daily lives. Radar as radio detection equipment is also the main application of slip rings. In the civilian field, slip rings are installed on aircraft, ships and for weather forecasting. And […]

Through-hole slip rings are the second largest production of JINPAT products. This type of slip rings is widely applied in various industries and people’s daily lives. Radar as radio detection equipment is also the main application of slip rings. In the civilian field, slip rings are installed on aircraft, ships and for weather forecasting. And given the different applications, slip rings are different.

In some low peak power radar systems for short-range detection, most have through-ring slip rings with a small through-hole and a small diameter. JINPAT Electronics has developed a pair of slip ring solutions for civil radar systems. JINPAT’s standard through-hole slip ring models can meet such needs. The most representative models are LPT012-0610, LPT038-1205 and LPT038-0605.

Generally speaking, standard through-hole slip rings are cost-effective products. However, some high-end radar systems require a special built-in slip ring. A radar system with high peak power generates a large amount of data. And in recent years, there has been an integration of radar and computer technologies. Sliding rings that transmit 100-meter Ethernet signals and Gigabit Ethernet signals are ubiquitous. The LPT000-36S-E2 is a built-in Ethernet sliding ring with 36 signal channels and 1,100M Ethernet signals.

For some large, higher-bandwidth radar systems, built-in slip rings with a single Ethernet channel are not sufficient. And RF rotary connection, also known as high-frequency slip rings, are key components to facilitate data transmission. LPT000-0315-0810- 80S-E3-HF03 and LPT060-0630-18S-E2-HF04 are two models of RF and Ethernet integrated slip rings, which are well received by customers.

Most JINPAT hollow shaft slip rings use traditional friction pairs of precious metal or fiber brushes. And on some large radars, sliding rings are mounted directly on the rotation shaft. As for radar with a large shaft diameter, the RF signal is not enough to ensure data transmission. To meet the requirements of this type of radar, JINPAT is developing a silver friction brush carbon graphite radar slip ring. These slip rings use an aircraft connector to facilitate the installation and maintenance of slip ring cables. As a pioneer in the production of slip rings, JINPAT Electronics also develops multi-channel integrated slip rings, integrated flat slip rings, and so on for various radar systems.

Keywords: radar slip ring, through-hole slip ring, hollow slip ring

JINPAT photovoltaic slip rings have high quality and competitive price. JINPAT has provided hundreds of models of electro-optical rotary joints for both civil and military industries. Most of JINPAT electro-optical slip rings have high transmission capacity. High-end slip rings can transmit 4K@60FPS high-definition video signals. OVERVIEW Design product sketches and models using SOLIDWORKS 3D Computer […]

With many years of experience in managing various types of projects, the management team of JINPAT is able to eliminate all obstacles that arise during the execution of projects to ensure that the technology is followed and the products are manufactured successfully. In addition, JINPAT understands the importance of good documentation. Documents such as certificates […]

JINPAT carries out precision machining of all components of its products. At all stages of production, from drawing to molding, JINPAT is committed to being precise and ensuring that the best slip rings are produced. With the ability to machine parts to a tolerance of 5 microns, our experienced, highly skilled team uses the latest […]

JINPAT welding technicians are experts in Gas Metal Arc Welding (GMAW), Flux Cored Arc Welding (FCAW), Gas Tungsten Arc Welding (GTAW) and Semi Metal Arc Welding (SMAW). They are dedicated individuals who value precision and aesthetics in the production of machine components. OVERVIEW Welding procedures comply with codes such as ASMEIX, AWS, DIN, API, B31.1, […]

JINPATElectronics is a customer-oriented corporation. We do our utmost to provide our customers with high-standard solutions for transmission including rotation. Up to now, JINPAT has provided its services to more than 10,000 customers worldwide. Each slip ring produced by JINPAT undergoes a series of rigorous and systematic inspections and durability tests before being delivered to […]

With advanced testing and measuring devices, JINPAT’s Quality Control Department conducts systematic inspections of our products. Our quality measurement system complies with ISO 9001:2015. JINPAT has great confidence in its products and has earned a good reputation for producing products of unrivaled quality. REVIEW Detailed inspection and provision of data in the form of documentation […]