Pipelines have the mission of passing the medium or whatever happens in the industrial scene on a daily basis. You will notice the importance of underground sewer systems when it rains heavily. Sewage systems need to be maintained regularly to ensure normal operation. The same applies to pipeline systems that work to transmit different types […]

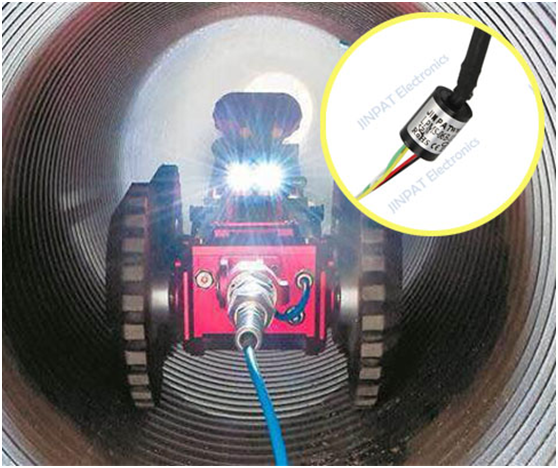

Pipelines have the mission of passing the medium or whatever happens in the industrial scene on a daily basis. You will notice the importance of underground sewer systems when it rains heavily. Sewage systems need to be maintained regularly to ensure normal operation. The same applies to pipeline systems that work to transmit different types of media. Regular inspection is necessary. For large diameter pipes, human penetration will not be a problem, but for safety reasons and for those with less space, robots are used to do this job. Pipeline robots are artificial intelligence devices that can easily penetrate pipelines and check the internal conditions of the pipeline. Slip rings are a necessary component that allows flexible movement of pipeline robot joints when transmitting power and signals. JINPAT Electronics, as a professional slip ring manufacturer, provides slip ring solutions for pipeline robots.

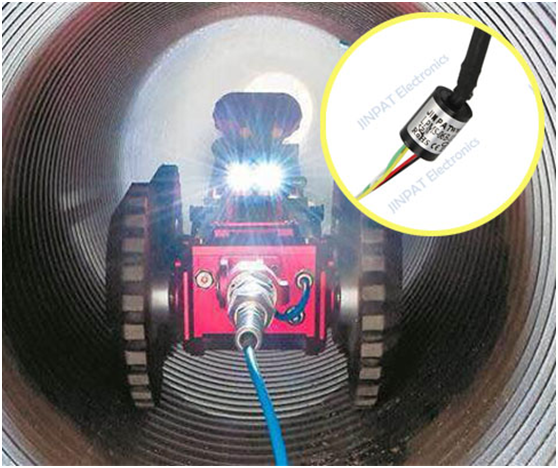

For the pipeline robots working in limited space, JINPAT Electronics recommends capsule slip rings LPC, miniature slip rings LPM and super miniature slip rings LPMS. In order to move freely in the pipeline, the figure of the inspection robot is strictly limited. That is to say, the slip rings must be tiny in size to fit into the corresponding pipeline robots. JINPAT LPC, LPM and LPMS are very small in size and light in weight. LPMS-06B-06S is a very typical slip ring model designed for pipeline robots. This super miniature slip ring with a diameter of 8.5mm and a length of 14.2mm can fit into the limited installation space. It is a 6-channel product with 2 signal channels, 2 analog channels and 2 left channels for other signals. Generally speaking, the slip rings are installed to allow the camera and joints of the robot to rotate. And to provide more vivid graphics transmission, sometimes integration of SDI and HDMI is required.

For conveyor robots with larger dimensions and more complex movements, slip rings are expected to meet higher power and more diverse functions, which usually leads to the selection of larger slip rings. Through-hole slip rings are the preferred choice due to their ease of installation on the robot shaft and their flexibility in integration. Especially for pipeline robots, which not only see through the pipeline condition but also carry out repair missions, precise and reliable connection movements are required. JINPAT through-hole slip rings are able to achieve precise and dynamic rotation while maintaining reliable data transmission. The through-hole design also provides great scope for further integration with other slip rings. Contact JINPAT Electronics for detailed information on our slip ring and rotary joint products, we also provide free consultation for customized design.

Key words: pipeline robot, small-sized slip ring, capsule slip ring, miniature slip ring, through slip ring

JINPAT photovoltaic slip rings have high quality and competitive price. JINPAT has provided hundreds of models of electro-optical rotary joints for both civil and military industries. Most of JINPAT electro-optical slip rings have high transmission capacity. High-end slip rings can transmit 4K@60FPS high-definition video signals. OVERVIEW Design product sketches and models using SOLIDWORKS 3D Computer […]

With many years of experience in managing various types of projects, the management team of JINPAT is able to eliminate all obstacles that arise during the execution of projects to ensure that the technology is followed and the products are manufactured successfully. In addition, JINPAT understands the importance of good documentation. Documents such as certificates […]

JINPAT carries out precision machining of all components of its products. At all stages of production, from drawing to molding, JINPAT is committed to being precise and ensuring that the best slip rings are produced. With the ability to machine parts to a tolerance of 5 microns, our experienced, highly skilled team uses the latest […]

JINPAT welding technicians are experts in Gas Metal Arc Welding (GMAW), Flux Cored Arc Welding (FCAW), Gas Tungsten Arc Welding (GTAW) and Semi Metal Arc Welding (SMAW). They are dedicated individuals who value precision and aesthetics in the production of machine components. OVERVIEW Welding procedures comply with codes such as ASMEIX, AWS, DIN, API, B31.1, […]

JINPATElectronics is a customer-oriented corporation. We do our utmost to provide our customers with high-standard solutions for transmission including rotation. Up to now, JINPAT has provided its services to more than 10,000 customers worldwide. Each slip ring produced by JINPAT undergoes a series of rigorous and systematic inspections and durability tests before being delivered to […]

With advanced testing and measuring devices, JINPAT’s Quality Control Department conducts systematic inspections of our products. Our quality measurement system complies with ISO 9001:2015. JINPAT has great confidence in its products and has earned a good reputation for producing products of unrivaled quality. REVIEW Detailed inspection and provision of data in the form of documentation […]