Slip rings, as a kind of rotating conductive parts that have emerged since the beginning of the second industrial revolution, have now reached perfection in the industry. How have professional slip ring manufacturers such as JINPAT developed their research and development? For a long time, JINPAT Electronics has insisted on investing a minimum of 3% […]

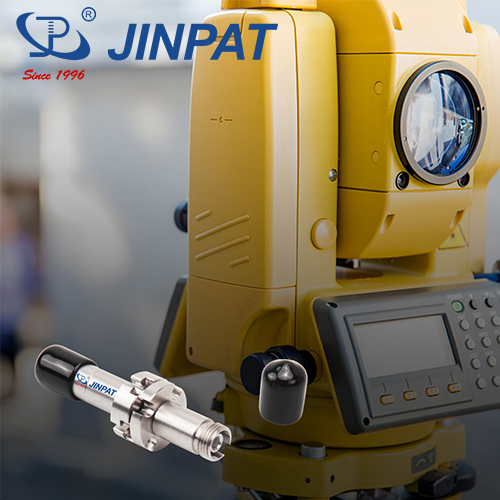

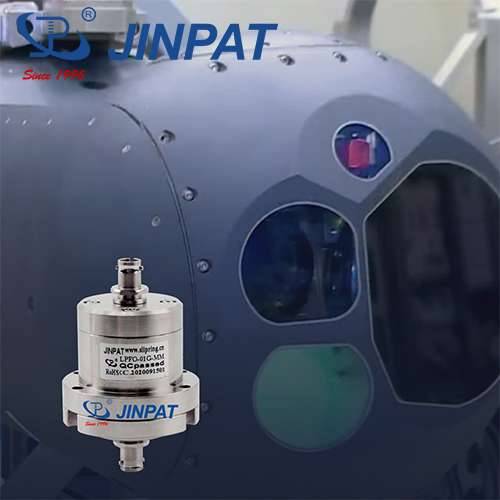

Slip rings, as a kind of rotating conductive parts that have emerged since the beginning of the second industrial revolution, have now reached perfection in the industry. How have professional slip ring manufacturers such as JINPAT developed their research and development? For a long time, JINPAT Electronics has insisted on investing a minimum of 3% of its annual operating income in R&D. By the end of 2022, JINPAT Electronics has obtained 62 national patent authorisations related to slip rings, of which 6 are invention patents. Relying on technology accumulation driven by long-term investment in R&D, JINPAT Electronics has made great achievements in the production of slip rings for automation equipment, slip rings for construction machinery, slip rings for consumer electronics, slip rings for medical equipment and precision instruments, slip rings for ultra-high voltage megawatt class electric motors. rings, military photovoltaic turret slip rings, high-frequency integrated slip rings, high-frequency integrated slip rings, and high-frequency integrated contact rings.

In fact, the most important part of the slip ring is the friction pair. In an electrical slip ring, there is a wire brush friction pair and a carbon brush friction pair. The ratio of the different materials of the friction pair affects the electrical performance (signal transmission) and service life of the electrical slip ring, as well as other decisive factors. Currently, the test bench of JINPAT’s Electronic Experiment Centre and Quality Control Department can simultaneously handle up to 400 units of slip rings with different functions to test the service life or electrical performance. The scale of this test equipment is the largest in the industry. Slip ring friction couple experiments test materials, so high and low temperature and salt aerosol resistance tests are mainly focused on some special materials. Of course, the slip rings that require these capabilities have a relatively special design, so in many cases JINPAT improves the structure of the product and also checks the performance and service life of the slip ring on the test bench.

JINPAT photovoltaic slip rings have high quality and competitive price. JINPAT has provided hundreds of models of electro-optical rotary joints for both civil and military industries. Most of JINPAT electro-optical slip rings have high transmission capacity. High-end slip rings can transmit 4K@60FPS high-definition video signals. OVERVIEW Design product sketches and models using SOLIDWORKS 3D Computer […]

With many years of experience in managing various types of projects, the management team of JINPAT is able to eliminate all obstacles that arise during the execution of projects to ensure that the technology is followed and the products are manufactured successfully. In addition, JINPAT understands the importance of good documentation. Documents such as certificates […]

JINPAT carries out precision machining of all components of its products. At all stages of production, from drawing to molding, JINPAT is committed to being precise and ensuring that the best slip rings are produced. With the ability to machine parts to a tolerance of 5 microns, our experienced, highly skilled team uses the latest […]

JINPAT welding technicians are experts in Gas Metal Arc Welding (GMAW), Flux Cored Arc Welding (FCAW), Gas Tungsten Arc Welding (GTAW) and Semi Metal Arc Welding (SMAW). They are dedicated individuals who value precision and aesthetics in the production of machine components. OVERVIEW Welding procedures comply with codes such as ASMEIX, AWS, DIN, API, B31.1, […]

JINPATElectronics is a customer-oriented corporation. We do our utmost to provide our customers with high-standard solutions for transmission including rotation. Up to now, JINPAT has provided its services to more than 10,000 customers worldwide. Each slip ring produced by JINPAT undergoes a series of rigorous and systematic inspections and durability tests before being delivered to […]

With advanced testing and measuring devices, JINPAT’s Quality Control Department conducts systematic inspections of our products. Our quality measurement system complies with ISO 9001:2015. JINPAT has great confidence in its products and has earned a good reputation for producing products of unrivaled quality. REVIEW Detailed inspection and provision of data in the form of documentation […]